Spare parts & OEM solutions

contact usCorrugated machinery parts

1.Corrugate belt

Corrugate belt

A double facer belt (also called a corrugator belt or double backer belt) is a specialized endless conveyor belt used in the double facer section of a corrugator line.

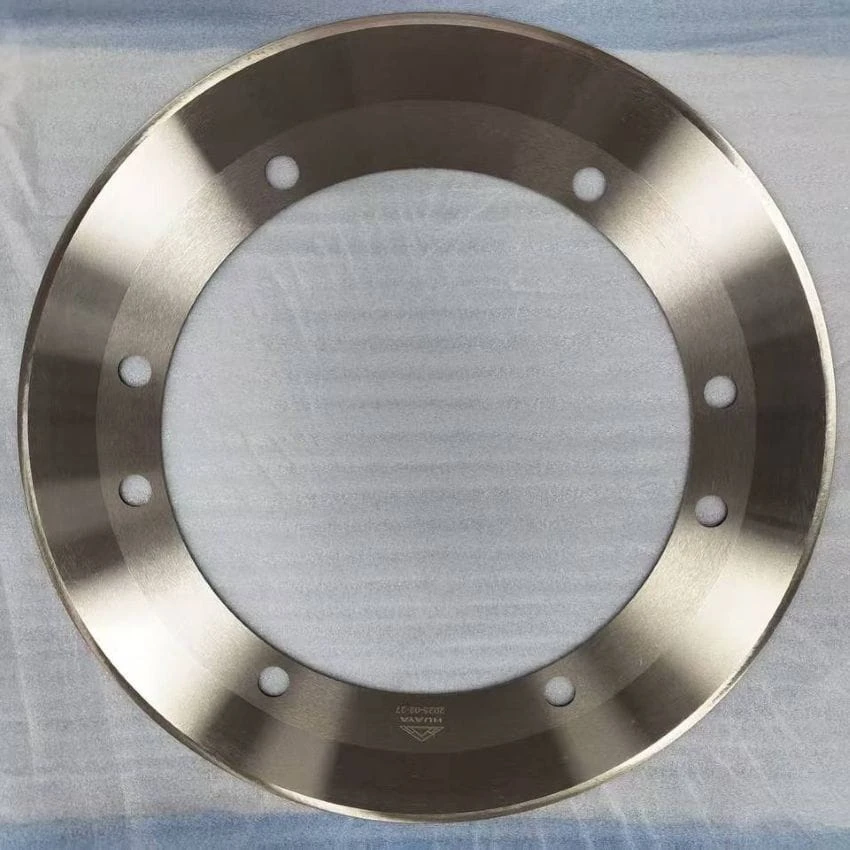

2.Razor blades

Razor blades

In the corrugated board industry, Razor Blades (slitter knives) are precision cutting tools used in slitter-scorer machines to trim, slit, or cut corrugated board or paper webs to the required width before converting.

3.Grinding stone

Grinding stone

In the corrugated board industry, a grinding stone (slitter knife grinding wheel or honing stone) is a precision abrasive tool used in slitter-scorer machines to sharpen rotary razor blades while they are in operation.

4.Cutoff knives

Cutoff knives

A cut-off knife in a corrugator line is a precision industrial blade mounted in the cut-off unit at the end of the line.

Its job is to cut the continuous web of corrugated board into sheets of exact length at high speed

5.No crush wheels

No crush wheels

No-Crush Wheels are specialized polyurethane rollers used in corrugators, inliners, and other converting equipment to transport, guide, or hold down corrugated board without damaging the flutes

6.Anvil covers

Anvil covers

An Anvil Cover (also called an anvil blanket, anvil pad, or lagging) is a replaceable polyurethane sleeve fitted around the anvil cylinder of a rotary die-cutter in the corrugated board industry

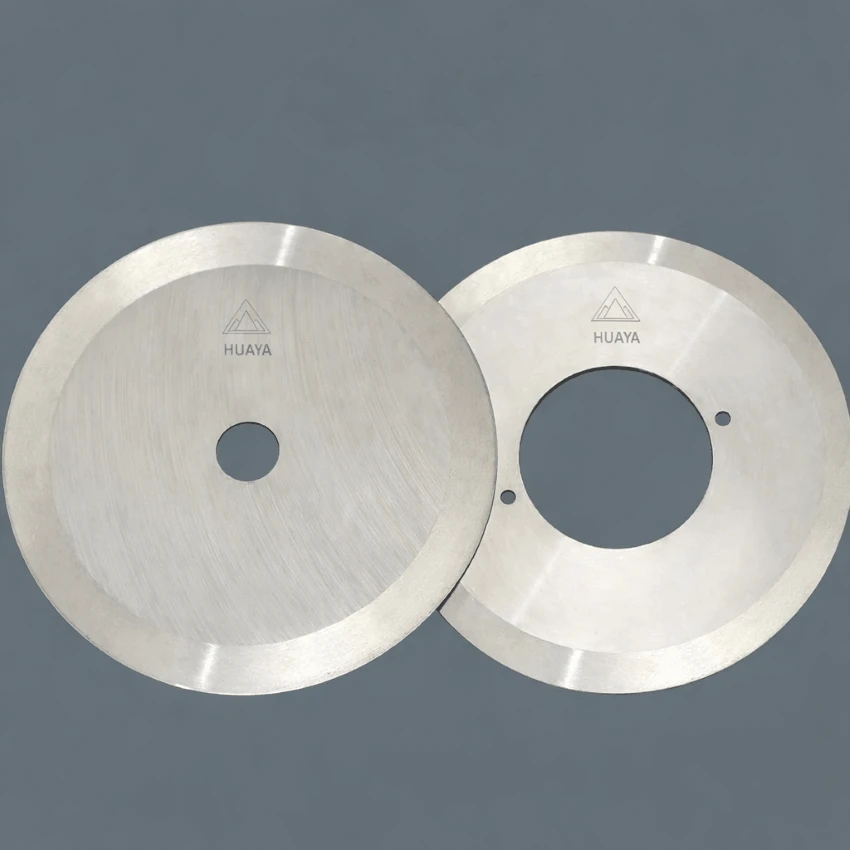

7.Slitter blades

Slitter blades

In the corrugated board industry, slitter blades (also called slitting knives or slitter scorer blades) are precision cutting tools used in the slitter-scorer section of a printing or converting machine

Pulp and paper components

1-Paper Machine clothing-general

Paper Machine clothing-general

Paper Machine Clothing refers to the engineered textile belts and fabrics used in different sections of a paper machine — forming, pressing, and drying — to transport, dewater, and support the paper web during production.

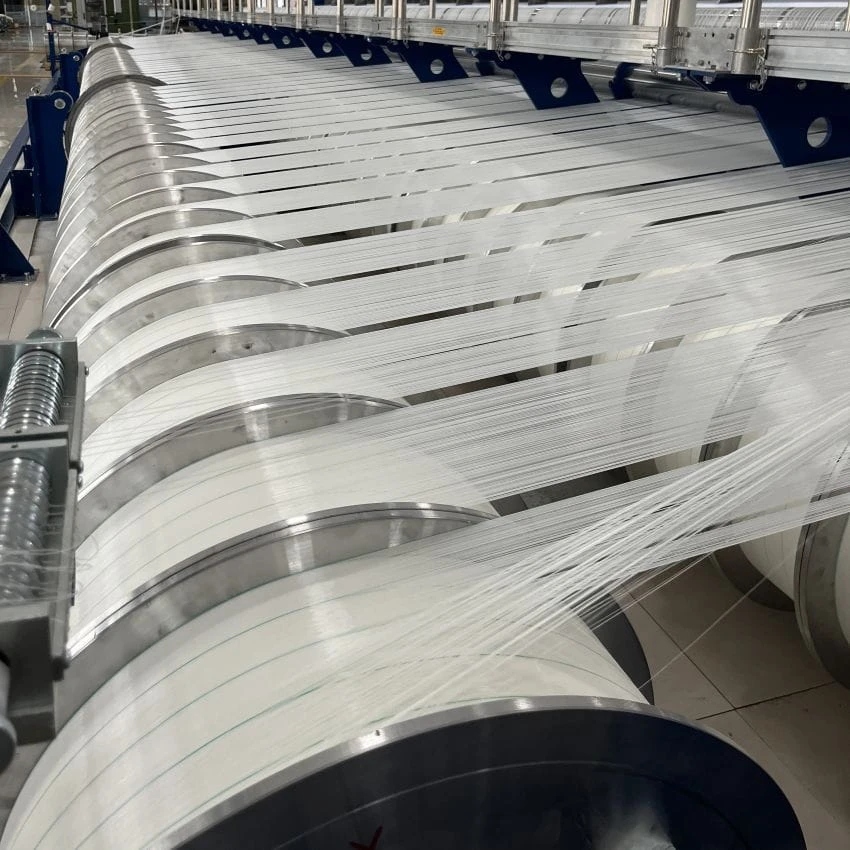

1-1.Paper machine clothing-forming fabric

Paper machine clothing-forming fabric

A forming fabric is a specialized woven synthetic mesh installed in the forming section of a paper machine. It supports the pulp slurry from the headbox, drains water rapidly, and forms the initial paper sheet by holding fibers in place while allowing water and fines to pass through.

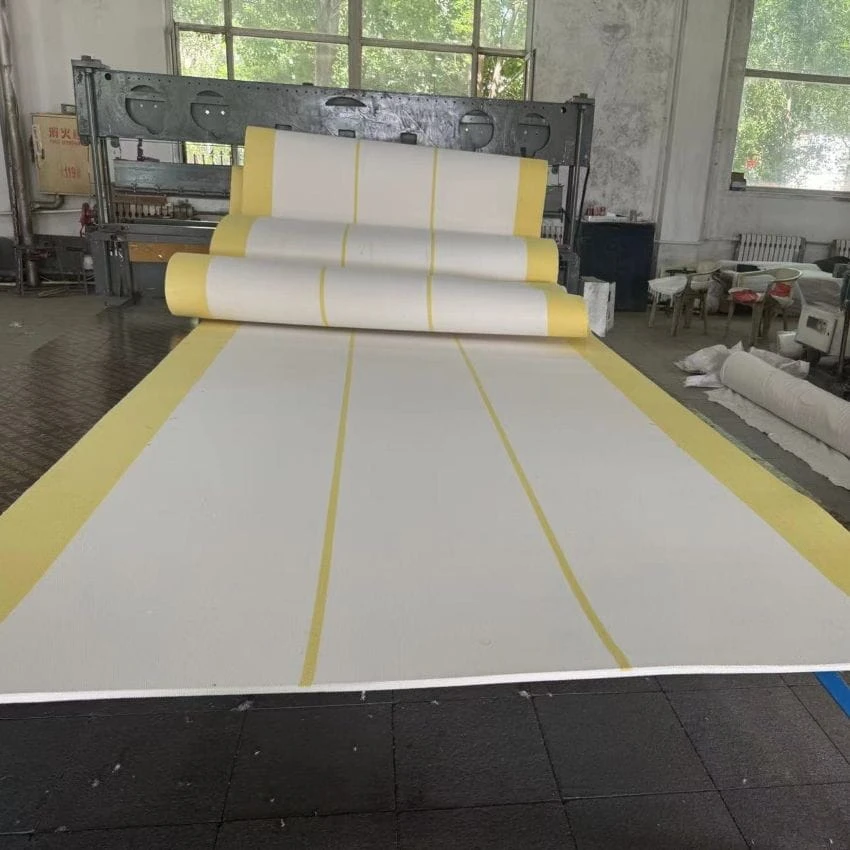

1-2.Paper machine clothing-press felt

Paper machine clothing-press felt

A press felt ( press fabric) is a specialized textile belt used in the press section of a paper machine.

Its main role is to support and carry the wet paper web through the press nips, absorb and remove water under pressure, and help transfer the sheet smoothly to the next section.

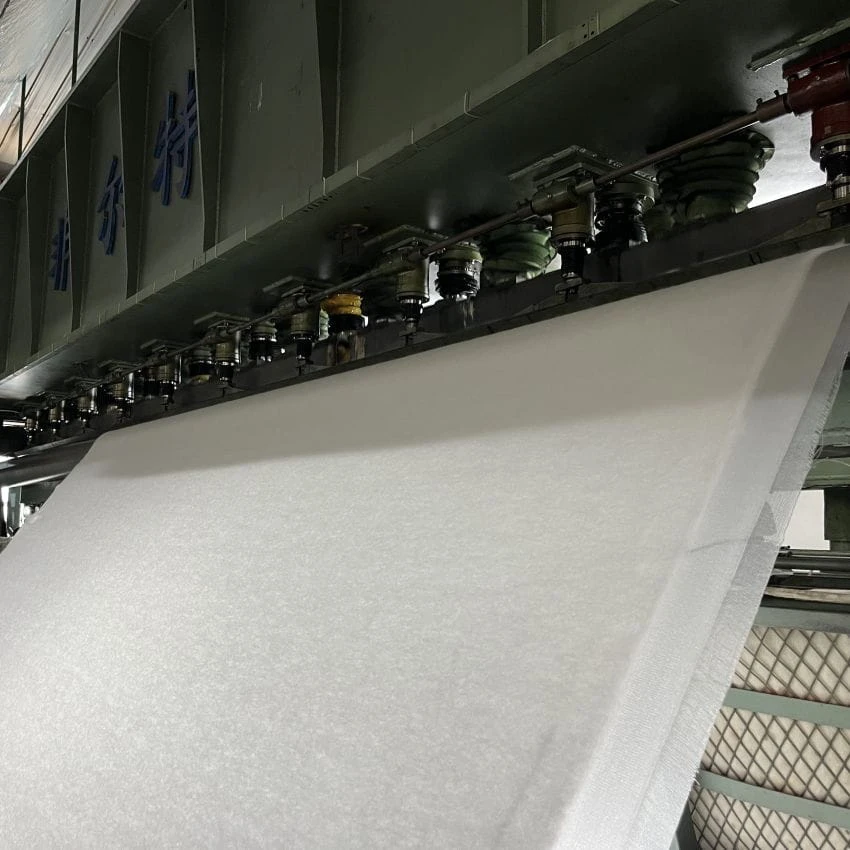

1-3.Paper machine clothing-dryer fabric

Paper machine clothing-dryer fabric

A dryer fabric (dryer screen, dryer clothing, or dryer felt) is a synthetic woven conveyor belt used in the dryer section of a paper machine. It also supports the sheet during transfers between cylinders, controls shrinkage, and contributes to sheet smoothness and runnability

2.Nozzles

Nozzles

In the pulp and paper industry, nozzles are precision spray components used throughout the paper machine and related processes to deliver controlled streams, fans, or mists of water, steam, air, or chemicals

3.Doctor blades

Doctor blades

In the pulp and paper industry, a doctor blade is a thin, precisely engineered strip mounted in a doctoring system to clean, control, or remove material from the surface of rolls and cylinders in a paper machine.

4.Rolls

Rolls

In the pulp and paper industry, rolls are cylindrical components installed throughout the paper machine and converting lines to support, convey, press, guide, or finish the paper web.

5.Winder knives

Winder knives

In the paper industry, winder knives (also called slitter knives or slitting blades) are precision cutting tools mounted in a winder or slitter‑rewinder to cut the wide paper web from the paper machine into narrower rolls of the required width.

6.Steam rotary joints

Steam rotary joints

A Rotary steam joint (also called a rotary union) is a mechanical device that allows pressurized steam to flow from a stationary supply pipe into a rotating dryer cylinder in a paper machine — and simultaneously allows condensate to exit via an internal siphon.

7.Screen basket & Mesh

Screen basket & Mesh

In the pulp and paper industry, Screens and Screen Baskets are essential components used in the stock preparation and screening phases. Their primary function is to separate contaminants and unwanted particles from pulp slurry, ensuring only high-quality fibers proceed to the next stages of production.

8.Dewatering elements

Dewatering elements

In the pulp and paper industry, Dewatering Elements are specialized machine components installed beneath the forming fabric in the wet end of the paper machine. Their primary function is to drain water from the pulp suspension, supporting sheet formation, improving drainage, and enhancing paper quality.